Live

- MLA assures help to flood-hit people

- Union Minister Bandi inaugurates hospital

- Incensed over HYDRA operations, dwellers threaten self-immolation

- Voluntary act by Jayabheri firm

- Farmers’ deaths not suicides, but murders by govt: Harish

- Bhatti calls for survey of rain losses, presents aid

- Naini hits back: BRS delayed Kalakshetram for commissions

- Minister Ponguleti blasts BRS for resorting to ‘mud politics’

- Flood threat looms over three villages

- Focus on controlling vector-borne diseases in flood-affected areas: Health Minister

Just In

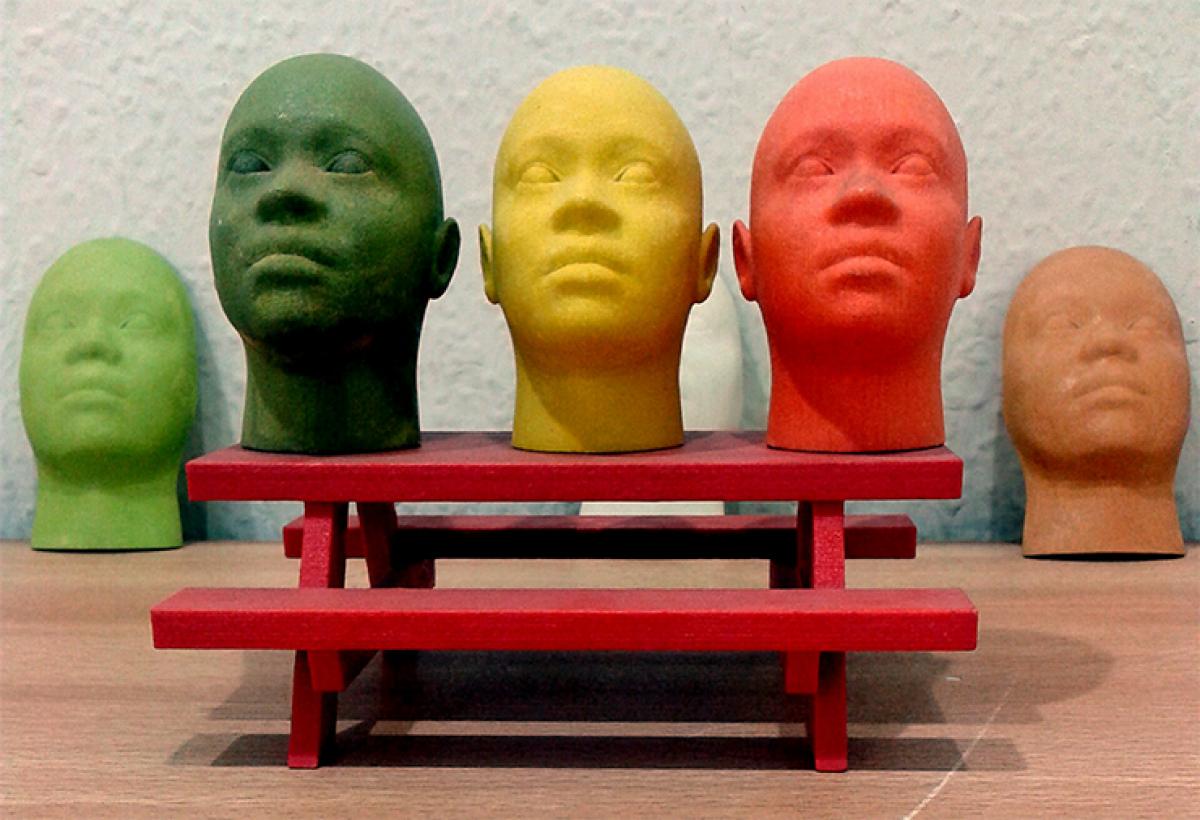

Researchers have managed to use cellulose from wood in a 3D printer to churn out a variety of three-dimensional objectS. The team also added carbon nanotubes to create electrically conductive material. The potential applications for such products range from sensors integrated with packaging, to textiles that convert body heat to electricity and wound dressings that can communicate with healthcare workers, the researchers said.

London: Researchers have managed to use cellulose from wood in a 3D printer to churn out a variety of three-dimensional objectS. The team also added carbon nanotubes to create electrically conductive material. The potential applications for such products range from sensors integrated with packaging, to textiles that convert body heat to electricity and wound dressings that can communicate with healthcare workers, the researchers said.

Cellulose and other raw material based on wood will be able to compete with fossil-based plastics and metals in the on-going additive manufacturing revolution. "Combining the use of cellulose to the fast technological development of 3D printing offers great environmental advantages," said research leader professor Paul Gatenholm from Chalmers University of Technology, Sweden. "Cellulose is an unlimited renewable commodity that is completely biodegradable."

The difficulty using cellulose in additive manufacturing is that cellulose does not melt when heated. Therefore, the 3D printers and processes designed for printing plastics and metals cannot be used for materials like cellulose. The researchers solved this problem by mixing cellulose nanofibrils in a hydrogel consisting of 95-99 percent water.

The gel could then in turn be dispensed with high fidelity into the researchers' 3D bioprinter, which was earlier used to produce scaffolds for growing cells, where the end application is paient-specific implants. The next challenge was to dry the printed gel-like objects without them losing their three-dimensional shape.

"The drying process is critical," Gatenholm said. "We have developed a process in which we freeze the objects and remove water by different means as to control the shape of the dry objects." Furthermore, the cellulose gel was mixed with carbon nanotubes to create electrically conductive ink after drying.

Carbon nanotubes conduct electricity and another project at Wallenberg Wood Science Centre aims at developing carbon nanotubes using wood. Using the two gels together, one conductive and one non-conductive and controlling the drying process, the researchers produced 3 D circuits, where the resolution increased significantly upon drying.

The two gels together provide a base for the possible development of wide range of products made by cellulose with in-built electric currents. The research results were presented at the conference 'New Materials From Trees' in Stockholm, Sweden, June 15-17.

© 2024 Hyderabad Media House Limited/The Hans India. All rights reserved. Powered by hocalwire.com