Live

- Maharashtra records 32.18 pc voting with bright spot Gadchiroli at over 50 pc

- BGT 2024-25: Indian team undergoes rigorous fielding sessions at Optus Stadium in Perth

- IPL 2025: Rishabh Pant will go at around 25-28 crore in the auction, claims Robin Uthappa

- Hardik reclaims No.1 T20I all-rounder spot; Tilak Varma soars into top 10

- Poor air quality surging dry eyes, allergies in children & adults: Experts

- Nokia wins multi-billion 5G deal from Bharti Airtel for India operations

- War of words over ‘bogus’ voting between Sharad Pawar faction and Ajit Pawar group in Baramati

- Delhi HC pauses money laundering trial against P. Chidambaram in Aircel-Maxis case

- Maoist’s killing: Cops went by law, no question of politics on security, says K’taka HM

- Date for resuming India-UK free trade talks to be finalised soon

Just In

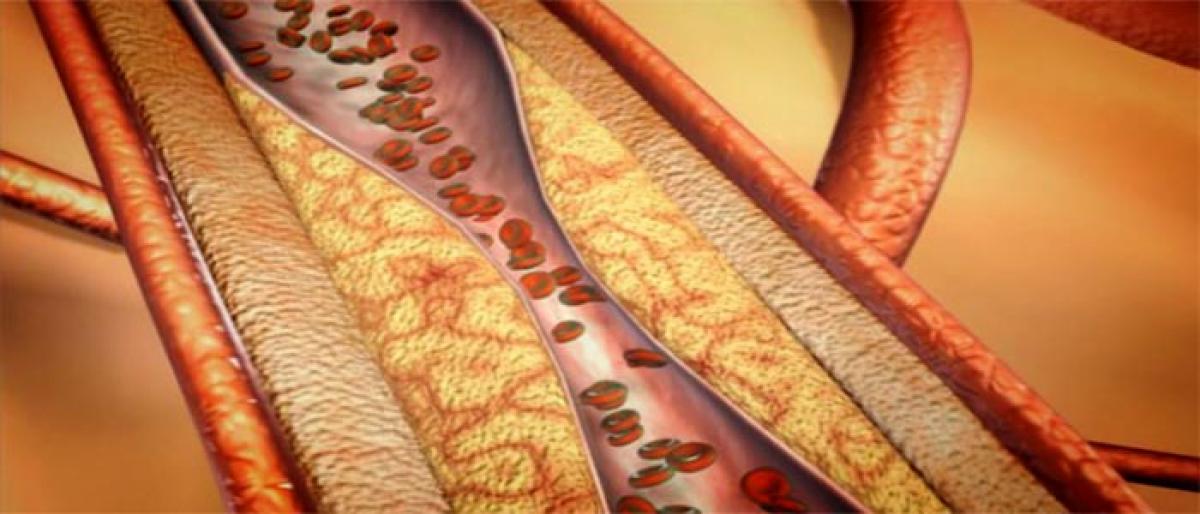

Percutaneous Coronary Angioplasty has become a well-established non- surgical method of treating patients with coronary artery disease. The technique was conceived off and first used in humans by Dr Andreas Gruentzig a German doctor on September 14, in Zurich, Switzerland. This was 10 years after the beginning of a regular program of coronary artery bypass surgery by Dr Favalaro at the Cleveland i

Percutaneous Coronary Angioplasty has become a well-established non- surgical method of treating patients with coronary artery disease. The technique was conceived off and first used in humans by Dr Andreas Gruentzig a German doctor on September 14, in Zurich, Switzerland. This was 10 years after the beginning of a regular program of coronary artery bypass surgery by Dr Favalaro at the Cleveland in USA.

Drug eluting Stent

The constituents of a typical DES are the metal platform in the form of a tube which consists of struts. The metal is stainless steel, chromium cobalt or platinum based alloys. This platform is mounted on an appropriately sized balloon. The balloon is connected to a shaft which is connected to an inflation device used to inflate the balloon. Expansion of the balloon deploys the stent at the pre-determined site of the blocked artery. The stent is coated with a polymer and drug combination. The polymer helps in a predictable release of the drug into the vessel wall. Polymers can be durable which last for ever or resorb able within a defined period of time, usually three to nine months. The durable polymers used in the new generation DES are very inert and safe (ex: everolimus eluting DES, Xience). However it is desirable that the polymer after completing its function of delivering the drug gets resorbed leaving only the metal well covered with body tissue. The qualities of a good stent are that it should be low in strut thickness, track able and conformable to the curvatures of the vessel wall. It should have a good radial strength so that the support to keep the artery open is adequate. The stents before being made available for patient use should have credible scientific data of efficacy and safety in Trials and Registries.

Bio-resorb able Stents

Intuitively the concept, that if the stent completely degrades after completing its function of scaffolding appears very attractive. In this direction after a lot of bench work Bio-resorb able vascular scaffold (BVS) became a reality. The product became available internationally including in our country. Within a few years of their release however its limitations became apparent. It had very thick struts, limited sizes, difficulty in deployment and moreover a significantly higher chance of getting blocked with clot formation. These problems have markedly limited their use and they are no longer available in our country. Even in Europe their use is limited to clinical trials alone. It is hoped that the new generation BVS would address these issues and make this very promising technology available again. Their long term benefits should lead to restoration of the vessel to normalcy with all its advantages.

Conclusion:

DES’s have become an important part of the non-surgical management of ischemic heart disease. Over the years significant advancements have occurred in the technology improving the efficacy and safety of these devices. The demand for these devices is steadily increasing in our country. It is time for the indigenous industry to rise to the occasion and compete with the established international industry. This needs research and development, state of art manufacturing facilities and scientific data in the form of non-inferiority trials and well conducted registries. The future is bright for the ‘Make in India’ concept.

© 2024 Hyderabad Media House Limited/The Hans India. All rights reserved. Powered by hocalwire.com