Live

- They always want me to win, and now I feel lucky to have been offered a story like ‘Zebra’: Satyadev Kancharana

- ‘Democracy first, humanity first’: PM Modi in Guyana's parliament on two countries' similarities

- PKL Season 11: Telugu Titans register third straight win to top standings

- Is Pollution Contributing to Your COPD?

- NASA Unveils Underwater Robots for Exploring Jupiter's Moons

- Additional Central forces arrive in violence-hit Manipur

- AR Rahman and Saira Banu’s Divorce: Legal Insights into Common Issues in Bollywood Marriages

- 82.7 pc work completed in HPCL Rajasthan Refinery area: official

- Curfew relaxation extended in 5 Manipur districts on Friday

- Tab scam prompts Bengal govt to adopt caution over fund disbursement

Just In

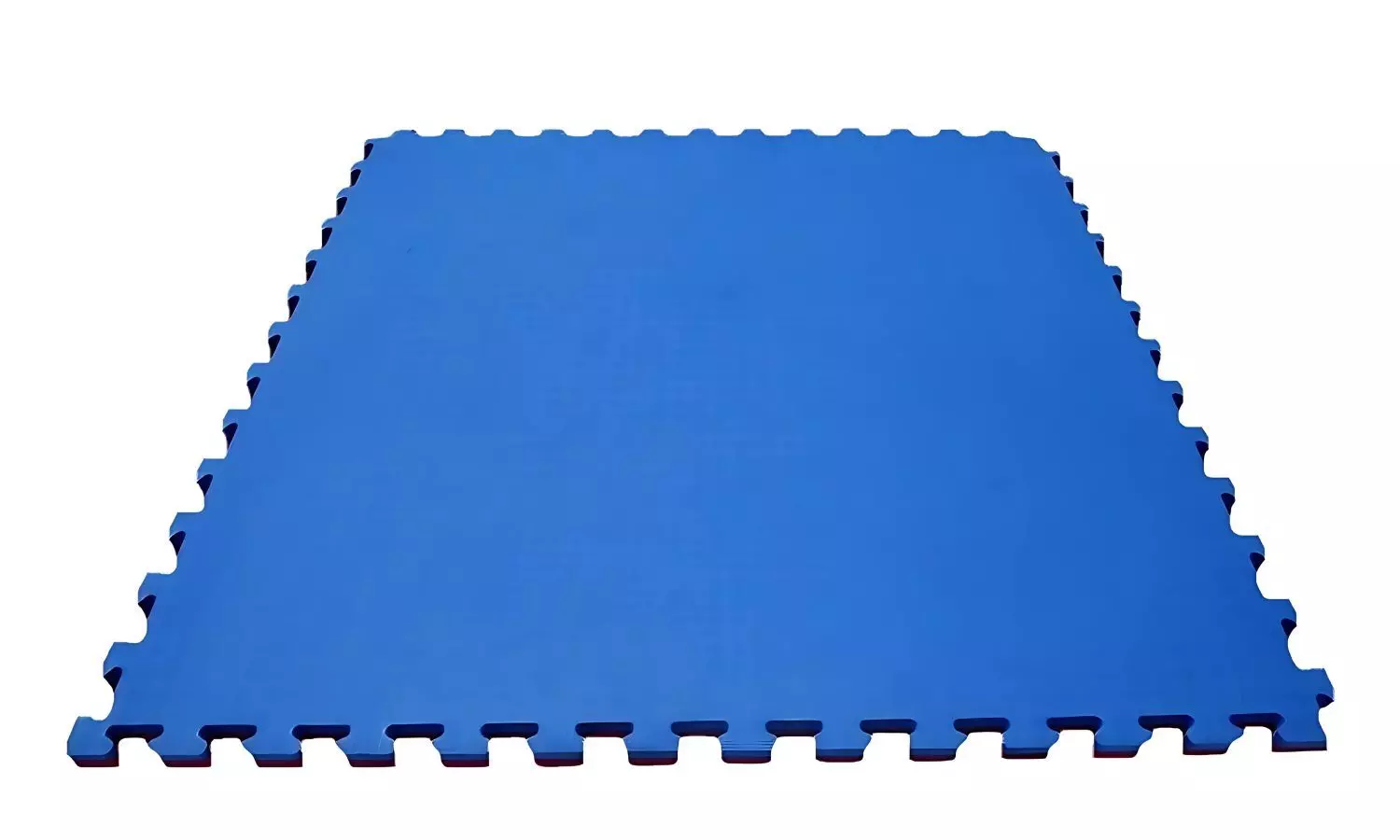

PKL Season 11: How are kabaddi mats made? What are the raw materials used? Gravolite details the manufacturing of kabaddi mats

Gravolite has been associated with the marquee league for some years now and they have been entrusted with the most important part of the kabaddi league – manufacturing, supplying and maintaining kabaddi mats

Hyderabad: The upcoming edition of the Pro Kabaddi League is set to roll from October 18 at the Gachibowli Indoor Stadium in Hyderabad. Teams are into the home stretch of their preparations, honing their skills with last-minute preparations, and so is Gravolite, a leading sports mats manufacturer.

Gravolite has been associated with the marquee league for some years now and they have been entrusted with the most important part of the kabaddi league – manufacturing, supplying and maintaining kabaddi mats.

Gravolite kabaddi mats have been prepared with state-of-the-art technology and taking into account the international standard cushion base and the floor cushioning.

The director of Gravolite, Paras Maheshwari, opened up on a variety of topics in a candid chat with the publication.

Excerpts:

Please detail about your association with PKL? When did it start?

We have been the manufacturer of mats for the PKL from the very start – that is, for the first few seasons, where we worked through vendors. Somehow, we saw some quality downgrade while working through the vendors and we approached PKL directly, and according to their specifications of materials we customise and make sure to prepare mats as per the international standards, keeping a close eye on the quality. For the last six or seven years, we have been directly associated with the league supplying them kabaddi mats.

Please explain the process of how the mats are made?

We use fundamental materials, we manufacture foam and raw materials constitute some petroleum products. Apart from these, there are blends of multiple rubbers which are made by our three rubber technologists. Our rubber technologist is equivalent to a person who is engineering the product. So, we put these raw materials, blend it and pressure it at a certain temperature and bake them for some time till we get a block out of it. After that,

We punch the block with a punching system, take different pieces from that and create an interlocking mat.

From where are the raw materials sourced? Where are the mats manufactured?

Our raw materials are enriched in petroleum and hence most raw materials are imported. Some of the raw materials are sourced from India, like from Reliance and the chemicals are also sourced from India only, although we import a fraction of them. We also get our raw materials from local traders as well. For manufacturing, we have our setup in Delhi as well as in Haryana for major production.

Please throw light on the testing process each mat undergoes before the final product is supplied?

We work on a vast scale, in terms of the kinds of product that we make. We have 10 to 12 grades on each mat. We make very small batches and their pitch, very small for final testing. We test in our small lab where we test the hard density and aspersion and there are multiple categories where we test every small batch after which we prepare in large quantities. We follow the same process for larger batches as well. After making the batches, we segregate it in different slots, after passing necessary quality checks, and we process them. The mats in A slot are the perfect product that we go ahead and supply for leagues like the PKL. The mats in slots B and C are used for different purposes, like in high-quality multi-purpose flooring like gyms and for soundproofing. We grade each slot differently for different purposes and the price is based accordingly.

What are the newer versions/adaptations/corrections etc. you have made for the 2024-2025 season of the PKL?

As far as the quality of the mat goes, we prepare a high-quality standard in the interlocking mat and for that we honestly don’t see any particular improvement we need in terms of raw material or in the finished products. However, there are some changes that the PKL team proposed to us as the colour, it might happen at the start of the game or at the end. We then try to change the whole face of the mat and that would be visible as multiple joints in the mat. If we talk about playing arena, mats would differ according to the size of the playing arena and the lobby area. The PKL follows the 230 x 240 mat with some extra lobby space.

Please detail on how much each mat costs?

The highest quality of mat we made, our MRP goes up to INR 3800 to INR 4000 per mat as ours are international federation-approved mats. Global kabaddi mats also cost around INR 4000 per mat plus the applicable taxes.

How is the maintenance of these mats done?

It is very easy to maintain the mats as long as they are in a covered environment. The mats cannot handle the sunlight directly as due to the UV cell structure, the mats can be damaged. Apart from that if the game is played with approved shoes by the federation, with little wear and tear the life of the mat is very long lasting. We only have to protect from dirt which we do with a normal thorough cleaning after every match, with water and cleaning substance.

© 2024 Hyderabad Media House Limited/The Hans India. All rights reserved. Powered by hocalwire.com